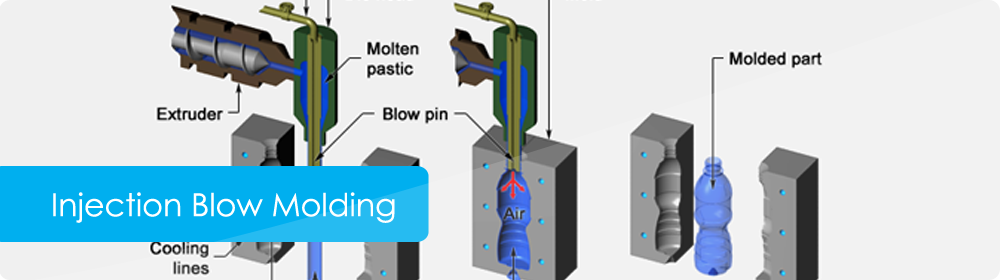

Injection Blow Molding is a process that combines traits of injection molding & blow molding and typically uses lower viscosity resins than those used in extrusion blow molding. Additionally, the process may be either a “one-step process” where the preform is molded on the same machine that it is blow molded on or, carried out using the “two-step process” where preforms are molded on an injection molding machine and then loaded into a second machine to be re-heated and inflated in the blow mold. Injection blow Molding is often preferred for small, complex bottles, such as those in medical applications.